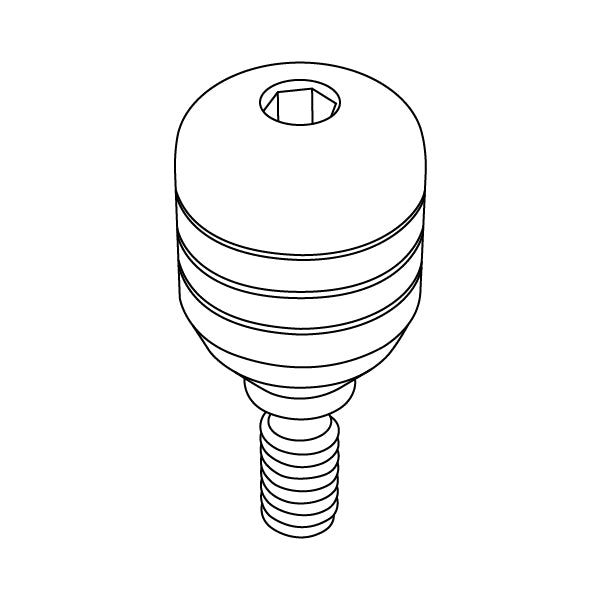

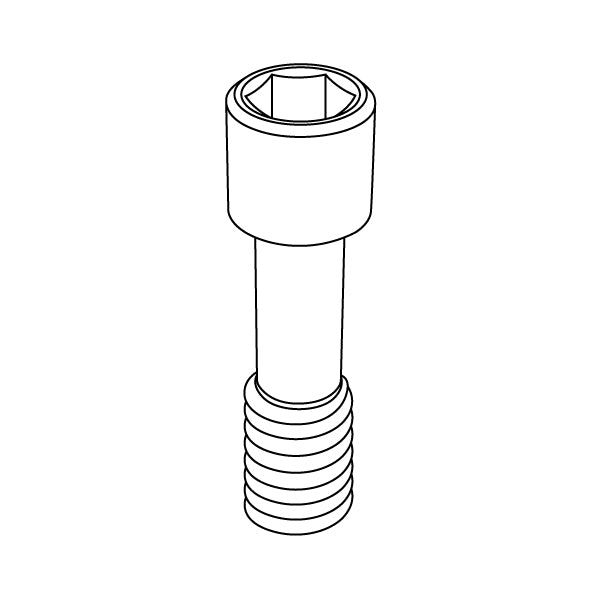

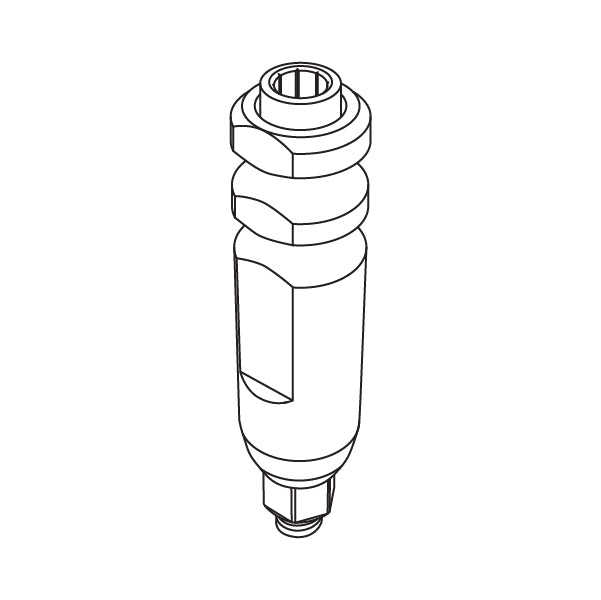

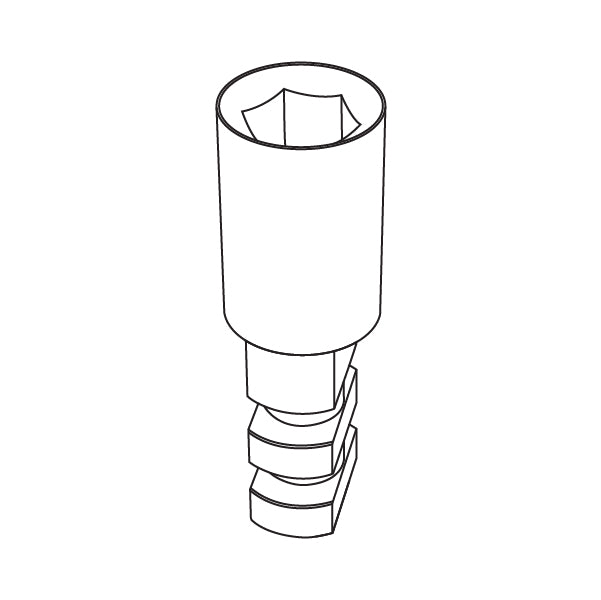

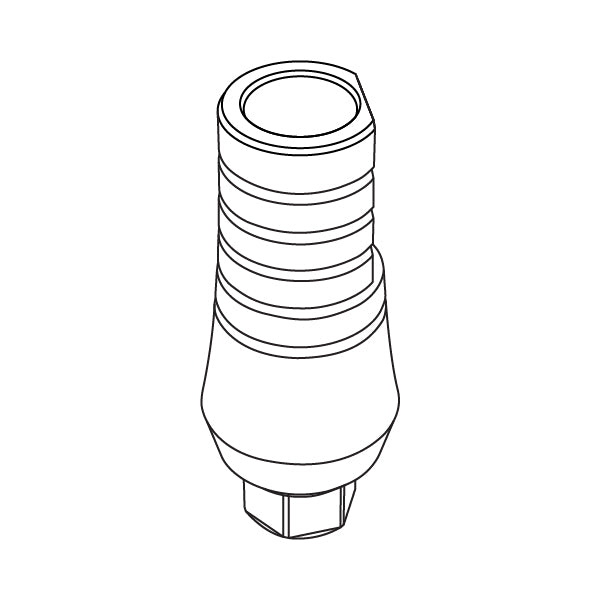

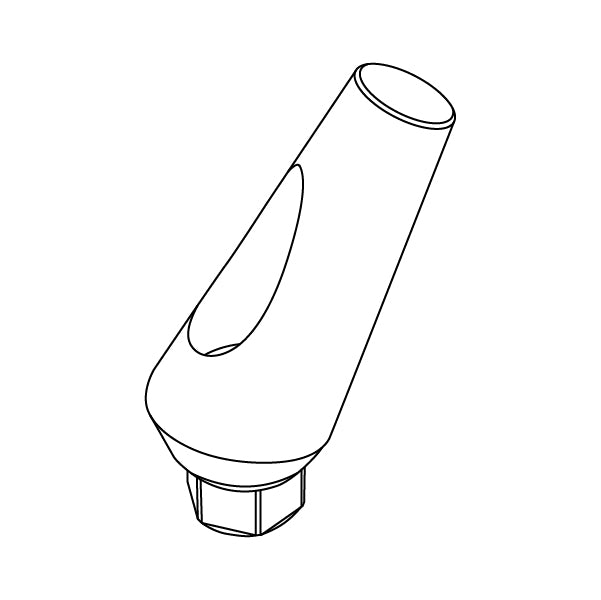

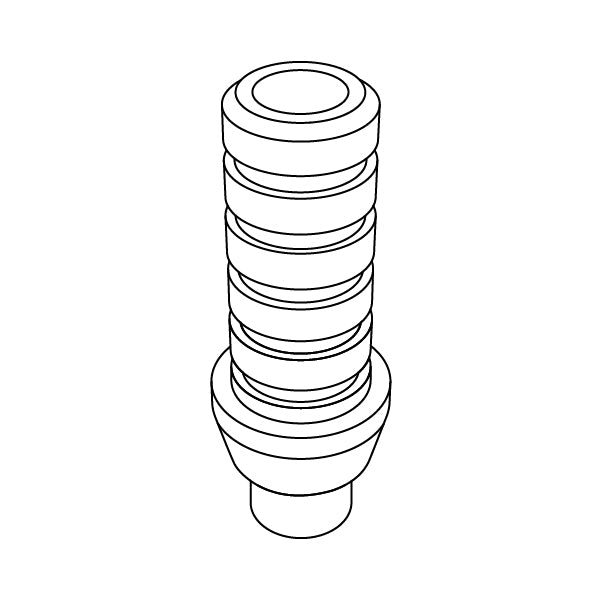

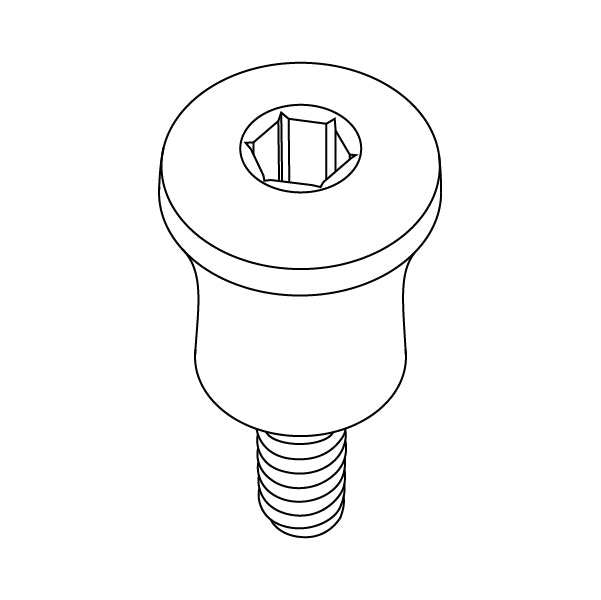

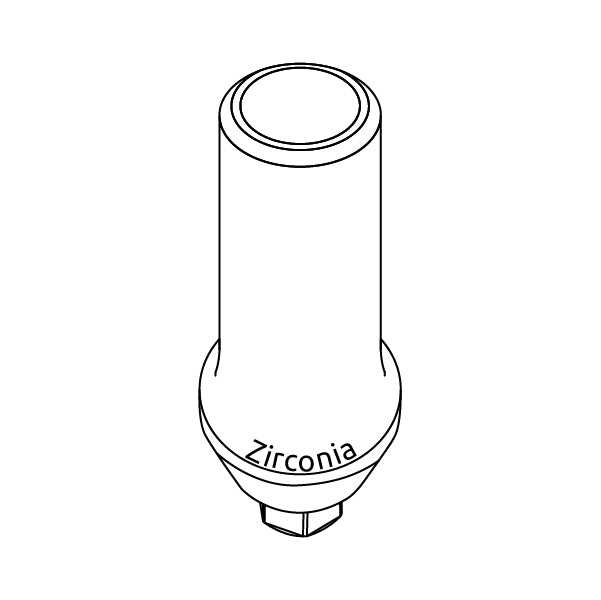

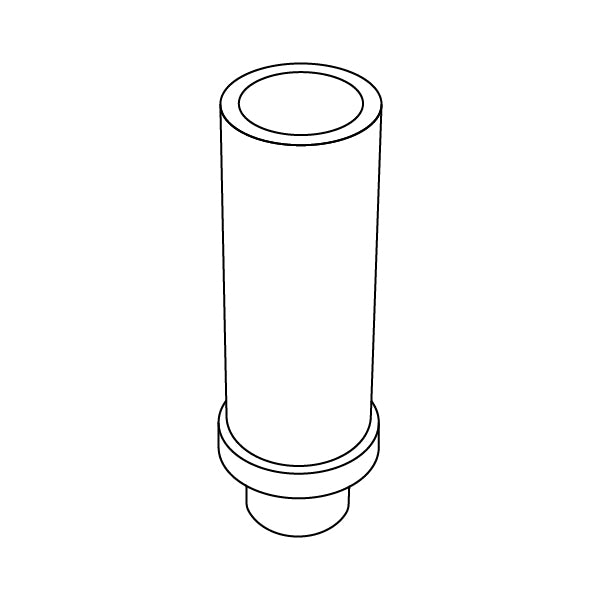

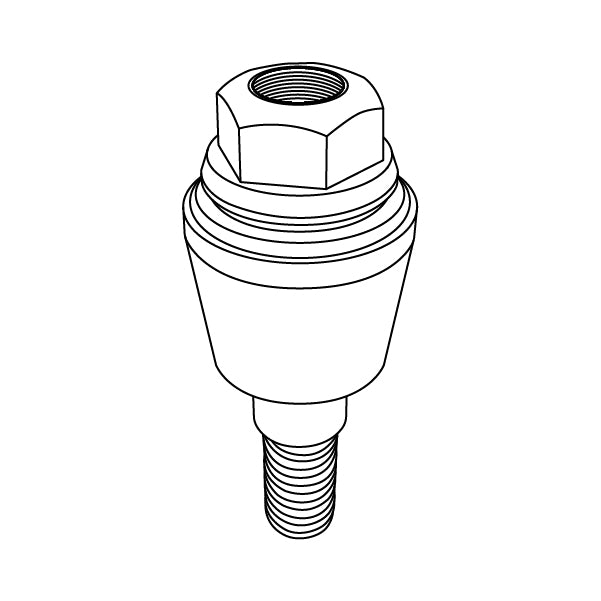

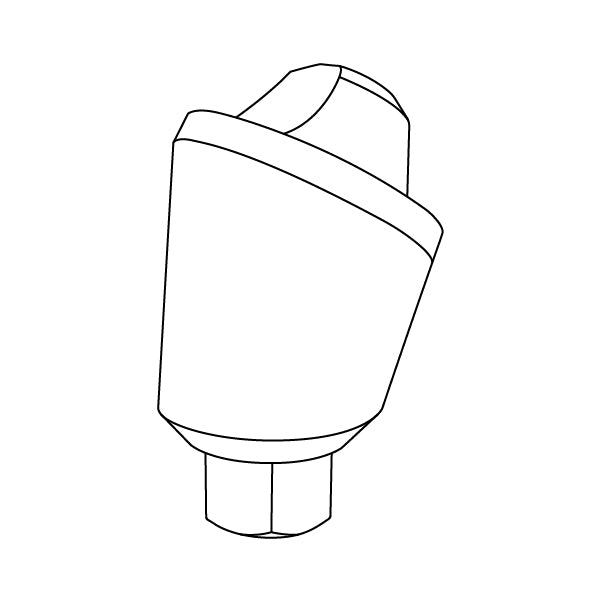

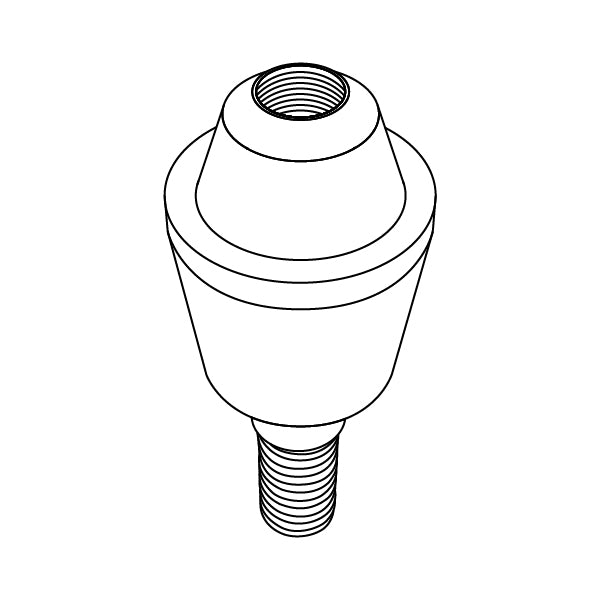

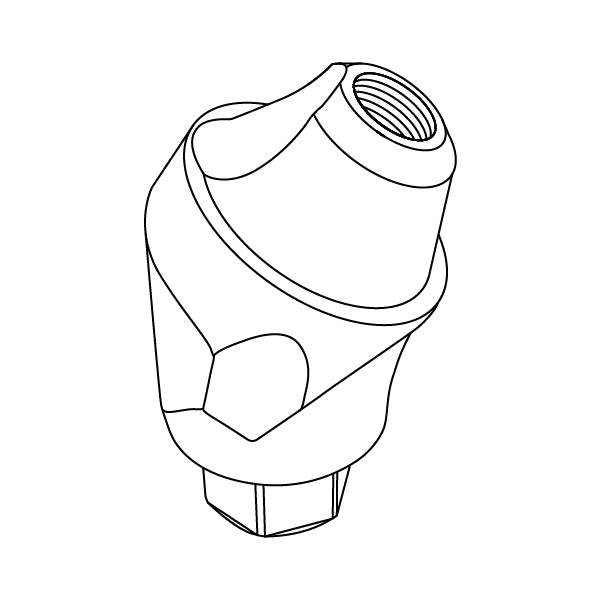

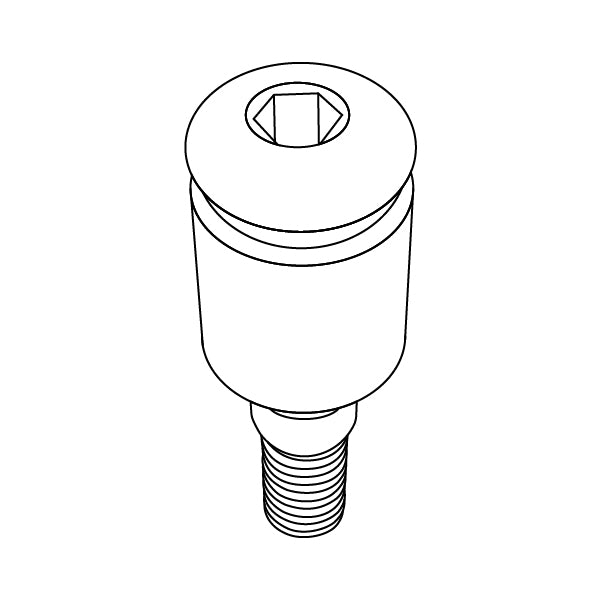

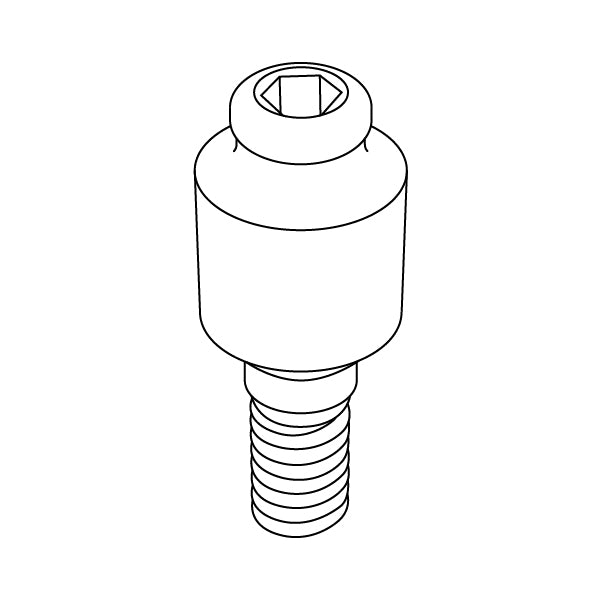

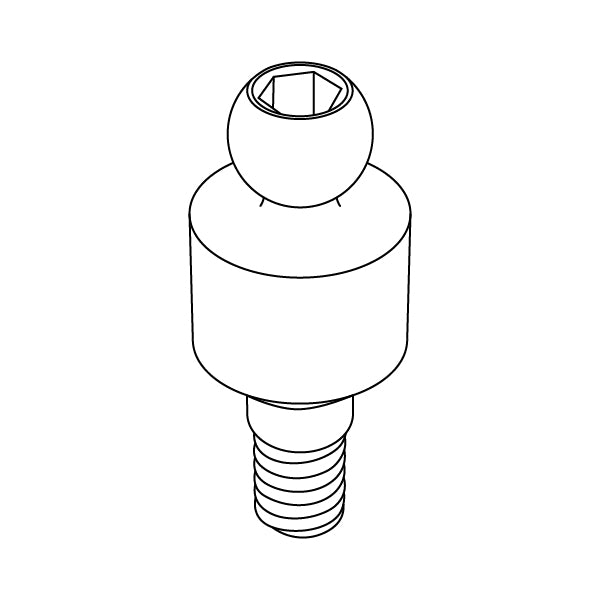

GDT CAD/CAM Abutments utilize advanced technology for the precise design of individual prosthetics like crowns, bridges, and implant-supported dentures. GDT Implants offers key components such as titanium bases, scan bodies, and analogs, easily captured through digital impressions. This enables the creation of a virtual model, forming the basis for accurate CAD/CAM abutment design and fabrication, ensuring optimal fit and function.

Additionally, GDT Implants provides a library for precise, cost-effective, and aesthetically pleasing restorations, streamlining workflows and enhancing overall quality in dental implant procedures. Download our CAD/CAM libraries for free.