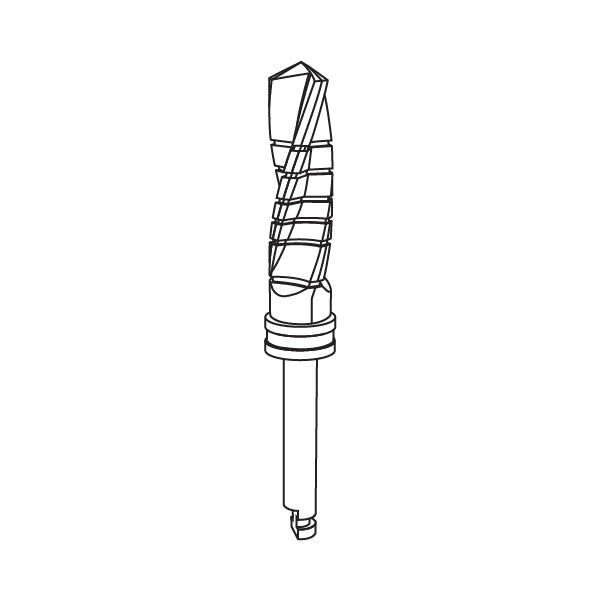

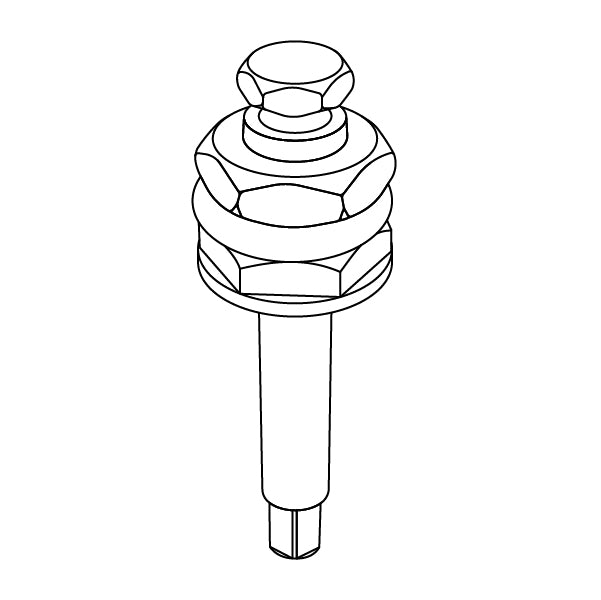

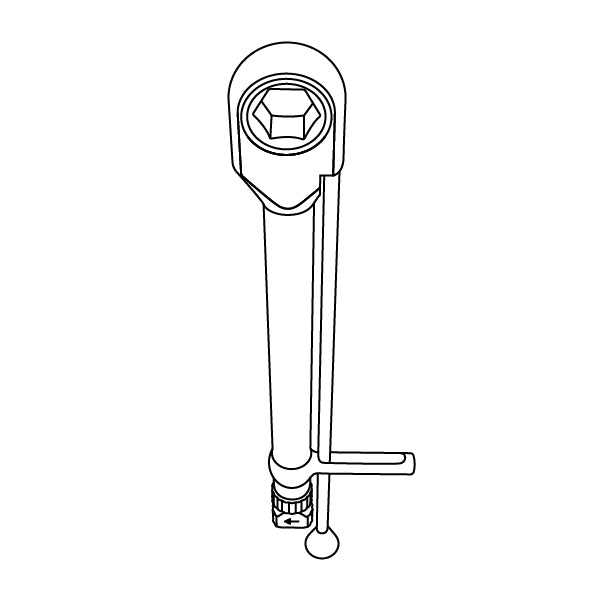

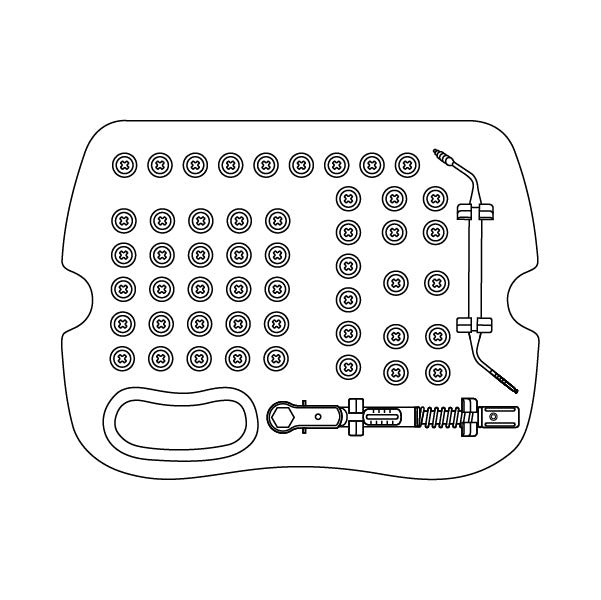

We provide an extensive selection of dental surgical instruments, including drivers for implants and prosthetics, drills, guide sleeves, pins, wrenches, and more.

Additionally, our comprehensive surgical kits offer everything from essential dental surgery tools to specialized instruments for niche procedures like broken screw extraction. Equip your practice with our premium tools to ensure precision and efficiency in every procedure.

Open Description

FAQs

Our surgical tools are meticulously designed to enhance precision in every phase of dental implant procedures. The ergonomic handle design ensures a comfortable grip, allowing for greater control and stability during surgery. Additionally, the tools are crafted with high-quality materials that maintain sharpness and integrity even after repeated sterilizations. These features work together to minimize the risk of slippage or mishaps during critical moments, providing dental professionals with the reliability needed for successful outcomes.

GDT Implants' surgical tools are primarily made from high-grade stainless steel, chosen for its exceptional strength and corrosion resistance. This ensures that the instruments maintain their structural integrity with frequent use and sterilization. Additionally, stainless steel helps keep cutting edges sharp for precise surgical incisions. Some of our tools are crafted from Titanium Grade 5, known for its lightweight and strength. By using these durable materials, our surgical tools offer long-lasting performance and reliability, making them a trustworthy choice for dental professionals.

The specialized coatings on our surgical tools are designed to enhance both functionality and longevity. For instance, the non-reflective coatings reduce glare from surgical lights, helping to improve visibility during procedures. Additionally, some of our tools feature a diamond-like carbon (DLC) coating, which increases the hardness of the tool's surface, reducing wear and extending the tool’s lifespan. These coatings also contribute to easier cleaning and maintenance, ensuring that the tools remain in optimal condition for repeated use.

At GDT Implants, we prioritize safety and effectiveness by adhering to strict quality control processes throughout the manufacturing of our surgical tools. Each tool undergoes rigorous testing to ensure it meets the highest standards for performance and safety. Additionally, our tools are designed with features that align with best practices in surgical procedures, such as precise measurements and clear markings for depth control. This commitment to quality helps ensure that our surgical tools perform reliably in clinical settings, supporting successful surgical outcomes.