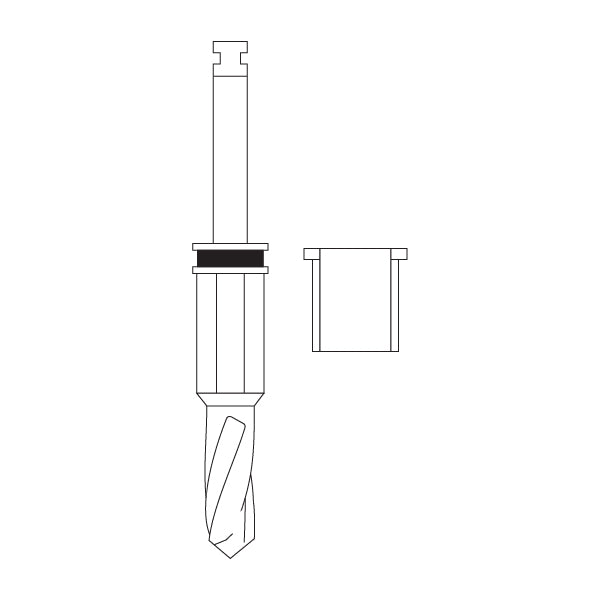

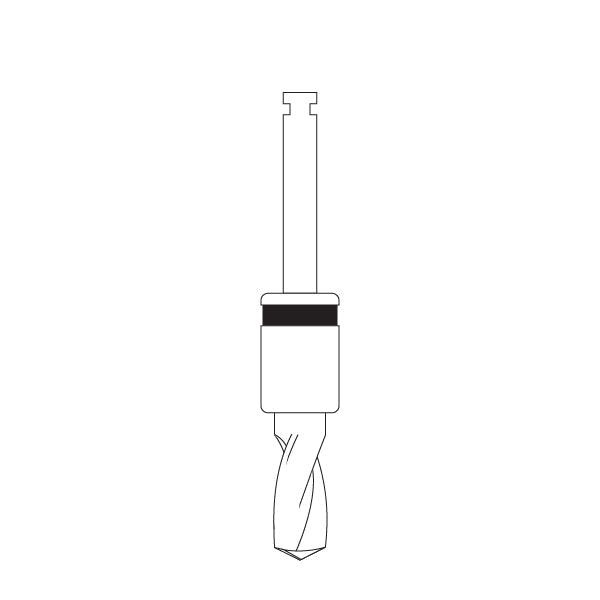

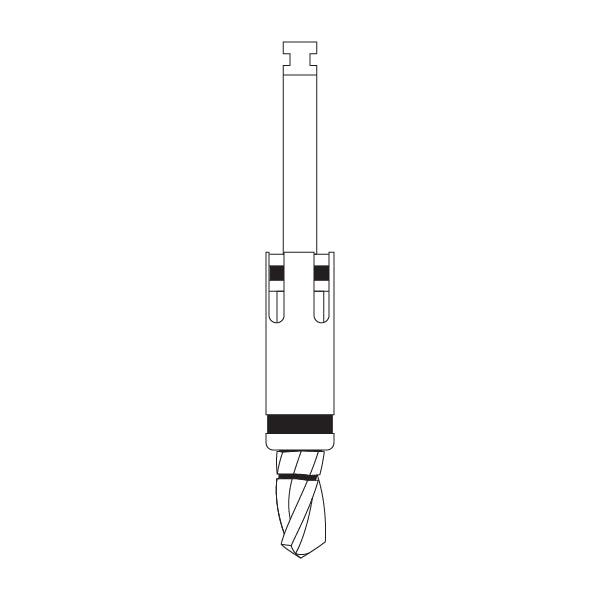

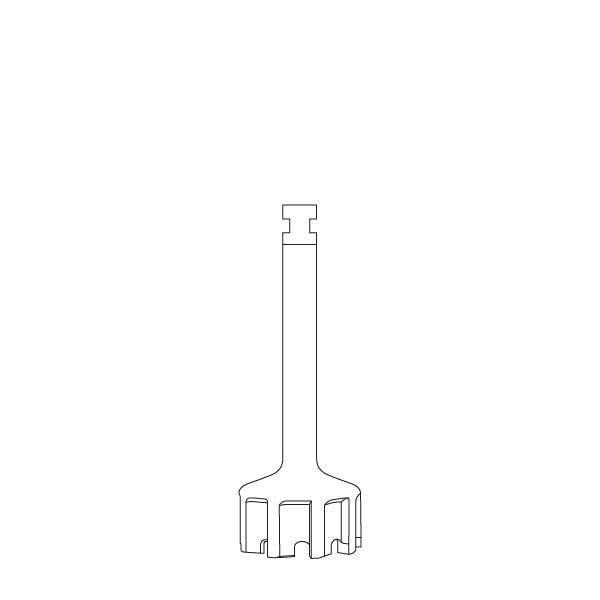

Our dental straight drills are made to accommodate various demands that dentists have. These drills have color-coded depth markings for simple identification and precise osteotomy depth control. They are available in two lengths, 11.5mm and 16mm.

These drills are made from premium stainless steel and come with DLC-coated versions for exceptional durability and cutting effectiveness. Our straight drills provide the reliability and precision needed for successful outcomes in your practice.

FAQs

Straight implantation drills are used in dental implant surgeries to create holes in bone tissue for the placement of implants, screws, or pins.

On top of that, straight drills enable the precise drilling of holes in bone tissue, ensuring proper placement of implants and other surgical hardware.

They are crucial in achieving successful surgical outcomes by providing accuracy and control during drilling.

Our straight drills operate by rotating at high speeds, allowing the drill to penetrate the bone tissue gradually. You can find the product in the following sizes on our website:

- Ø2.0mm

- Ø2.5mm

- Ø2.8mm

- Ø3.0mm

- Ø3.2mm

- Ø3.5mm

- Ø3.65mm

- Ø4.0mm

- Ø4.2mm

- Ø4.5mm

- Ø4.8mm

- Ø5.2mm

- Ø5.5mm

- Ø5.8mm

The drill bit creates a straight hole with minimal tissue damage, ensuring optimal conditions for implant placement.

When selecting straight drills, it's essential to consider the drill's diameter, length, material composition, and compatibility with surgical instruments and procedures.

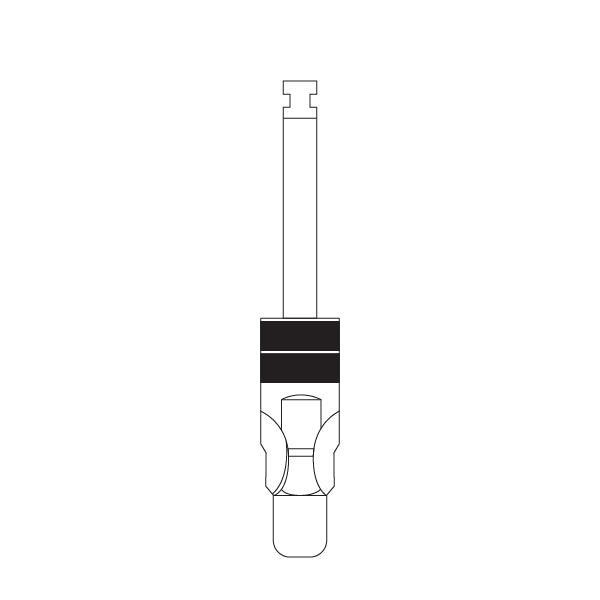

The DLC straight drills, for example, have a length of 16.0mm. On top of that, the material is stainless steel, with a carbon DLC coating on top.

GDT Dental Implants' products are also corrosion-resistant and long lasting. You'll find black depth marks on all straight drills to ensure maximum visibility.

Follow manufacturer guidelines for cleaning, disinfection, and sterilization processes, using appropriate cleaning solutions. Contact us here if you have any questions regarding maintenance.

Choosing the right drill sizes for oral implantology procedures depends on various factors. This includes the specific implant system you're using, the bone density of the patient, and the surgical technique you want to use.

Each implant type comes with a guide that outlines the recommended drill sizes for various implant dimensions. However, these guidelines should be considered recommendations rather than strict rules. When selecting the appropriate drill size, it's crucial to assess all aspects of the case, including the patient’s bone density and the specific location within the jaw. Leveraging your professional expertise, you can evaluate these factors to make an informed decision that best addresses the needs of the specific surgical situation.

DLC (Diamond-Like Carbon) coated drills provide significant performance and longevity advantages, making them an essential part of the dental implant toolkit. They are particularly valuable in high-volume practices or situations that require precise and efficient bone drilling. The DLC coating helps these drills maintain their sharpness and precision over a longer period, even after repeated use. Additionally, the smooth surface of the coating enhances their cutting efficiency, allowing for cleaner and more precise cuts. This feature is crucial as it minimizes the heat generated during drilling, which is important because excessive heat can damage bone tissue and negatively impact the healing process.