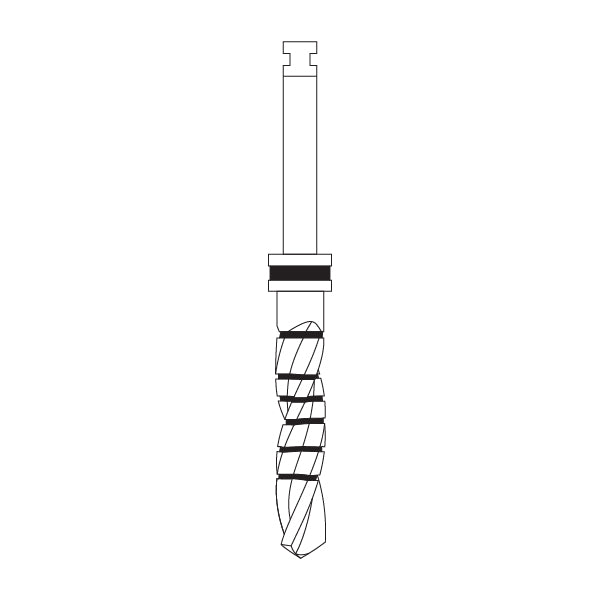

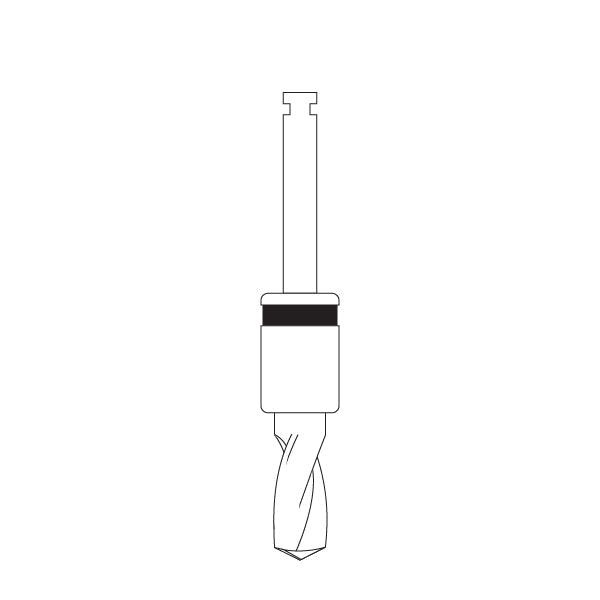

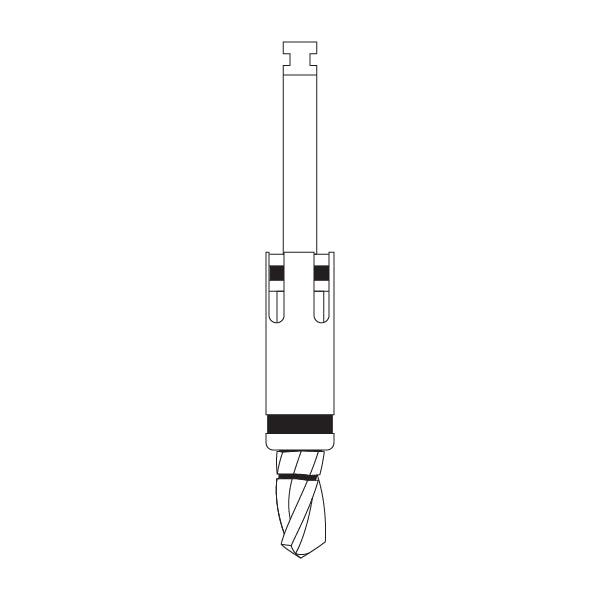

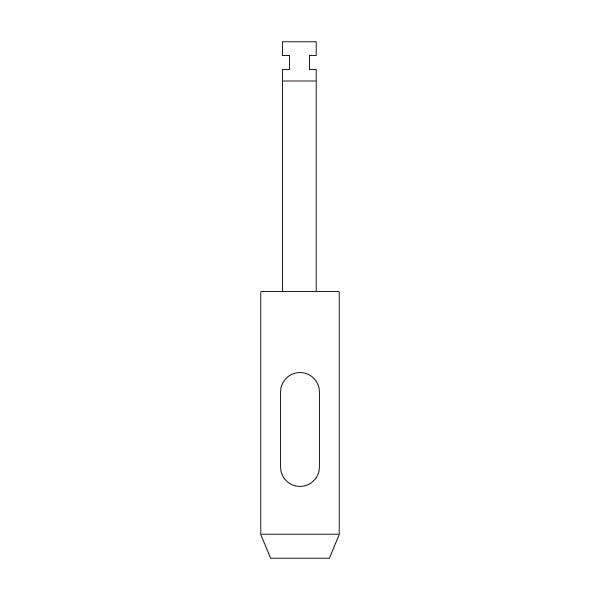

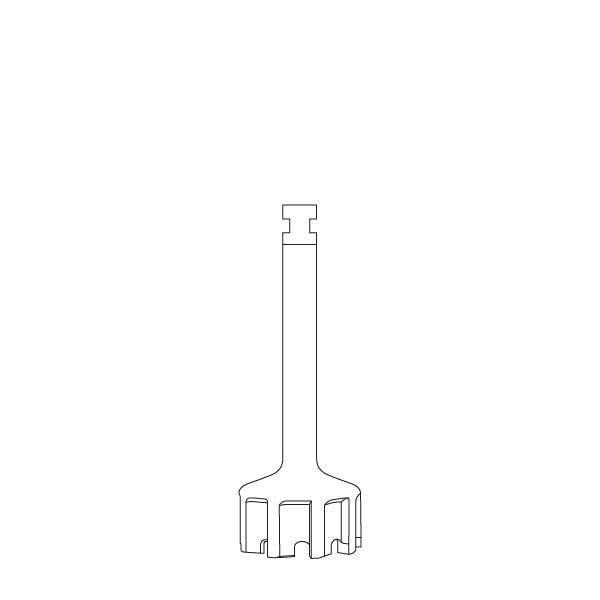

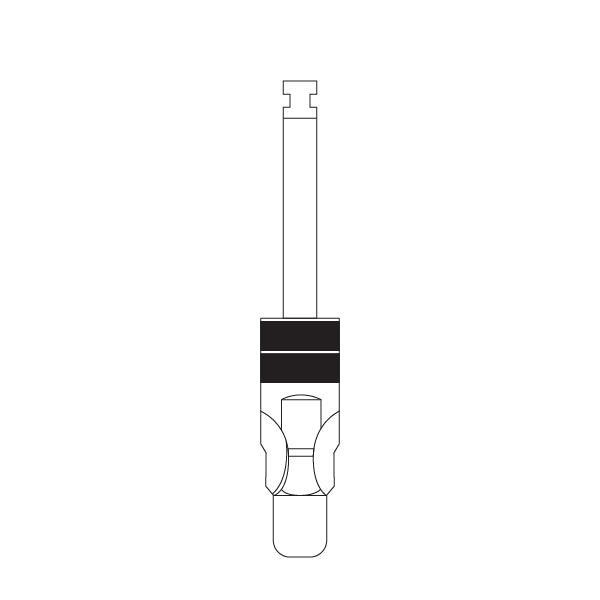

Guided surgery drills are essential tools in dental implantology, designed for use with surgical sleeves to ensure accurate and precise drilling. Crafted from stainless steel, these drills feature built-in stoppers to enable predictable and efficient implant placement, reducing the risk of errors and improving patient outcomes.

Open Description

FAQs

GDT Implants' Guided Surgery Drills are meticulously engineered to ensure precision and safety during implant placement. The drills feature depth markings that are laser-etched for enhanced visibility and accuracy, allowing dental technicians to maintain control over drilling depth consistently. Additionally, these drills are designed with specific diameter variations to accommodate different stages of bone preparation, ensuring the optimal fit and stability of implants. The sharpness and cutting efficiency of the drill bits also minimize heat generation, reducing the risk of bone damage during the procedure.

Material selection is crucial in the performance and longevity of GDT Implants' Guided Surgery Drills. We utilize high-grade surgical stainless steel, known for its strength and corrosion resistance, which ensures durability even after multiple uses and sterilization cycles. The material's hardness contributes to maintaining the sharpness of the cutting edges, which is essential for precise and efficient drilling. Furthermore, the stainless steel used is selected for its ability to withstand high temperatures and stress, providing reliable performance during guided surgeries.

GDT Implants' Guided Surgery Drills are designed to enhance clinical precision, which is critical for achieving successful patient outcomes. The drills work seamlessly with surgical guides, ensuring that the angulation and depth of each implant are precisely controlled, thereby reducing the margin for error. This precision helps in avoiding complications such as improper implant placement or damage to surrounding anatomical structures. By facilitating accurate implant positioning, these drills contribute to the long-term success and stability of the dental restorations, improving patient satisfaction and clinical results.

To ensure the longevity and performance of GDT Implants' Guided Surgery Drills, it is important to follow proper maintenance practices. After each use, the drills should be thoroughly cleaned to remove any debris or biological material. Sterilization should be carried out according to the recommended protocols, avoiding excessive temperatures that could affect the integrity of the drills. It is also advised to regularly inspect the drills for signs of wear, such as dullness or deformation, and to replace them as necessary to maintain surgical precision. Proper storage in a dry, sterile environment further extends the lifespan of these tools.