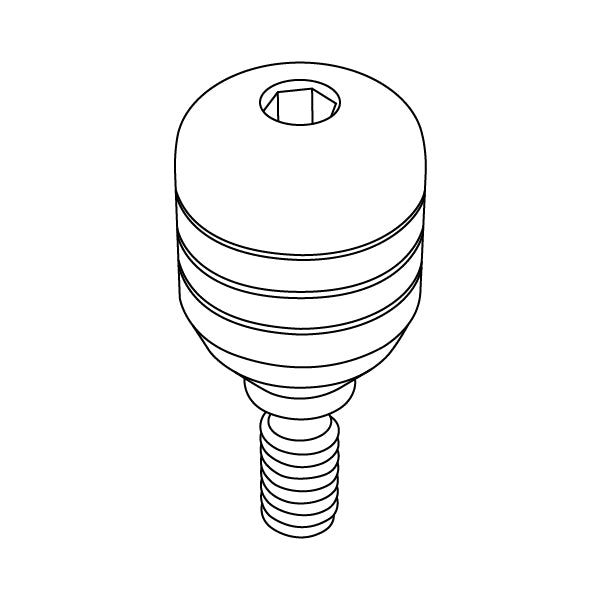

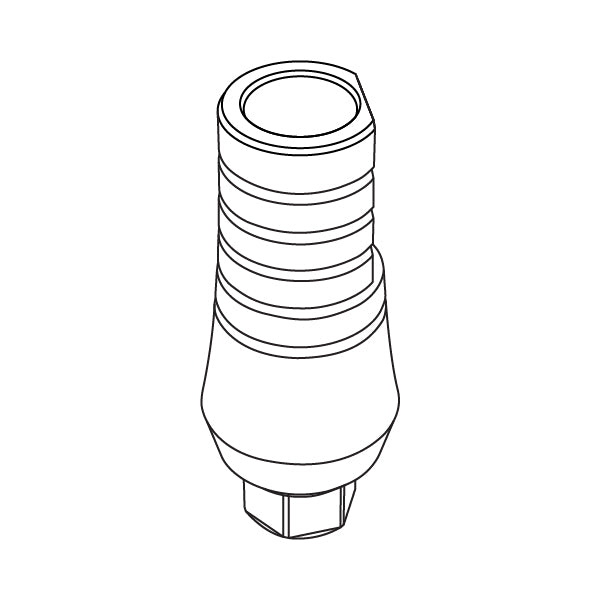

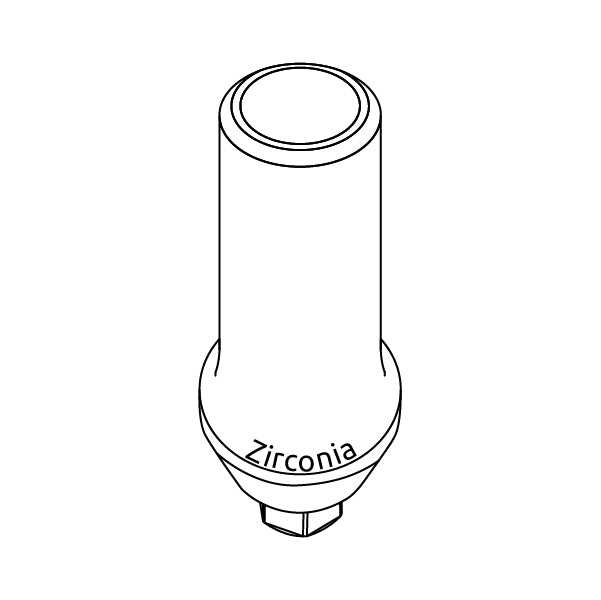

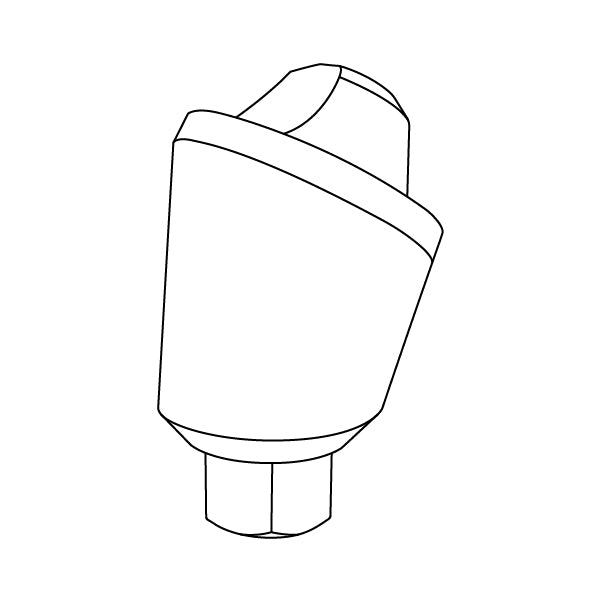

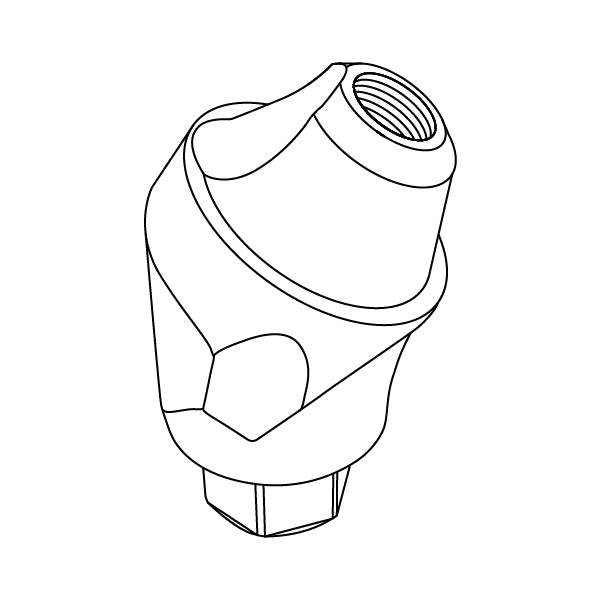

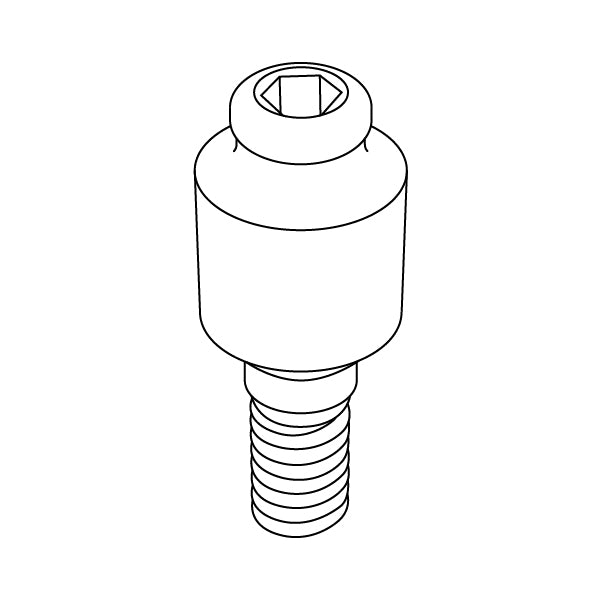

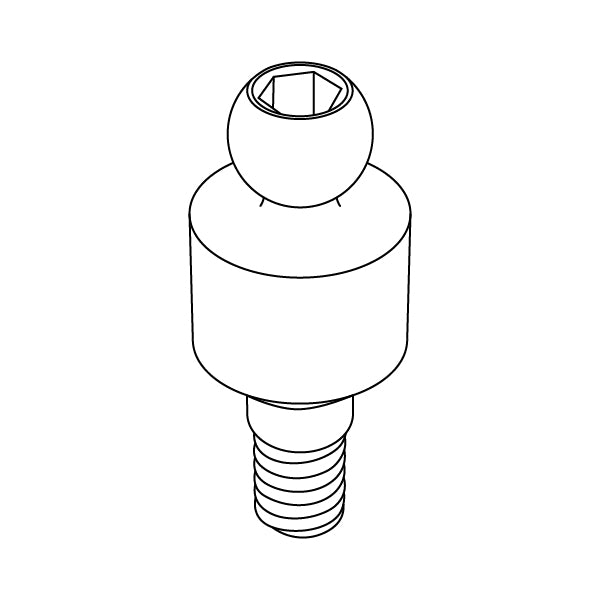

Angulated 1.6 multi-unit abutments, available in 17°, 30°, and 45° angles, are designed to meet the demands of advanced dental restorations. The angled design allows for precise alignment in challenging cases, ensuring optimal aesthetics and functionality.

Ideal for use with bridges and dentures, angulated 1.6 multi-unit abutments offer versatile solutions for restoring multiple missing teeth.

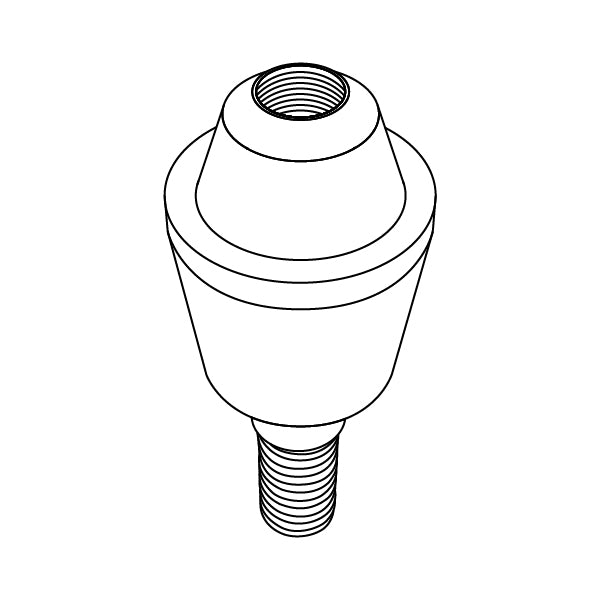

These abutments, crafted from premium Titanium grade 5 (Ti-6Al-4V ELI), provide exceptional durability and biocompatibility. Enhance your dental practice with these reliable and cost-effective abutments, engineered to deliver superior patient outcomes.

Open Description

FAQs

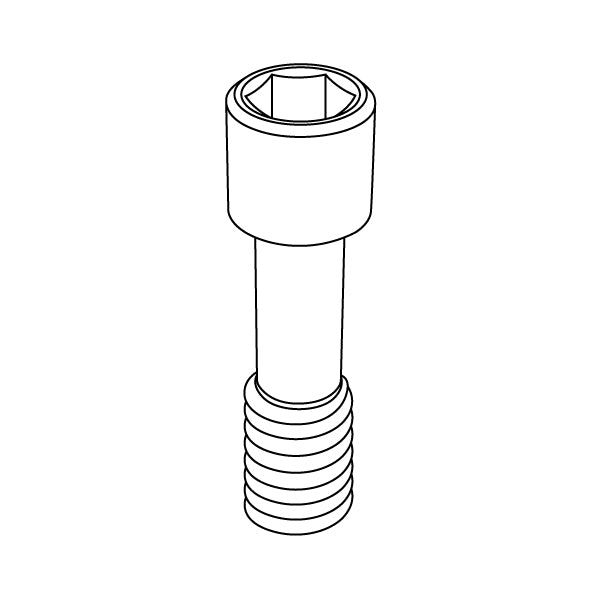

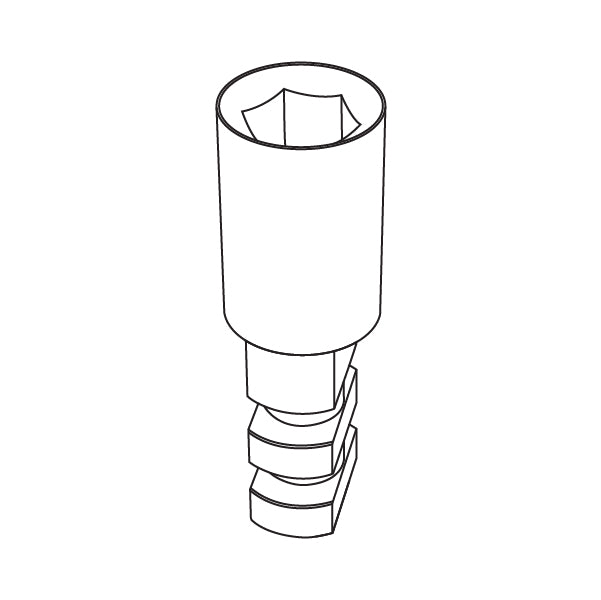

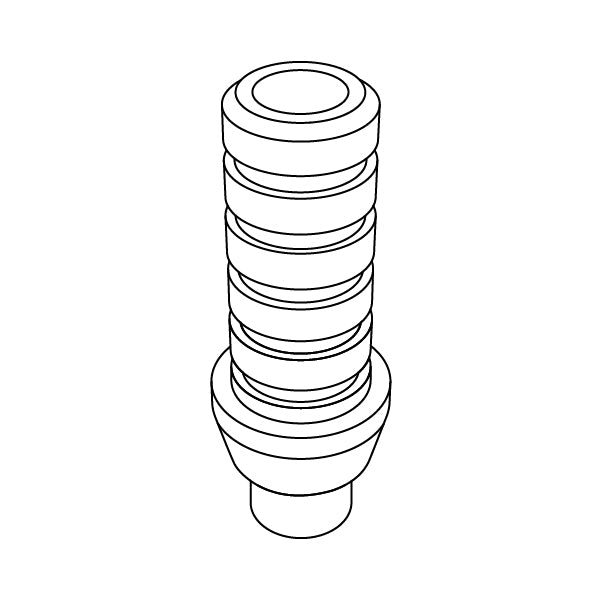

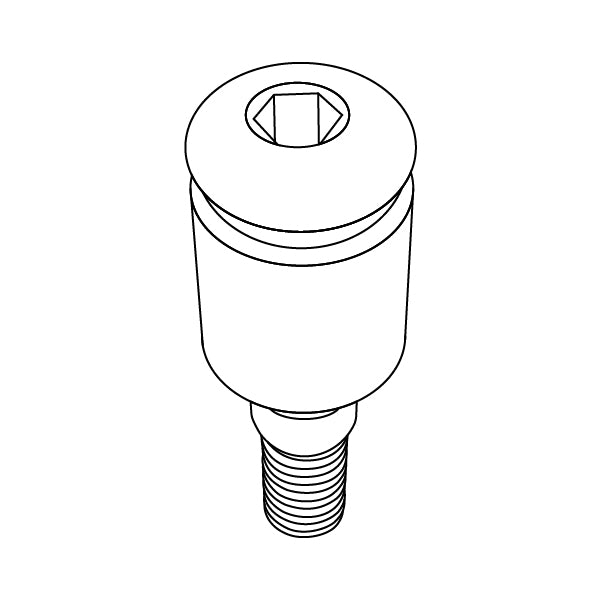

The primary difference between Multi-Unit 1.6 and Multi-Unit 1.4 abutments lies in their screw thread diameters, with the Multi-Unit 1.6 having a 1.6mm screw and the Multi-Unit 1.4 having a 1.4mm screw. The larger 1.6mm screw provides increased mechanical stability and strength, making it suitable for cases requiring higher load-bearing capacity, such as full-arch restorations or areas with higher masticatory forces. This size also offers easier handling and manipulation during placement and adjustment.

In contrast, the Multi-Unit 1.4, with its smaller screw diameter, is better suited for less demanding cases or where anatomical constraints limit the use of larger screws. It is ideal for use in anterior regions or situations where precision is required, such as in delicate anatomical areas. While it still provides adequate stability, the 1.4mm screw is particularly useful in constrained spaces or for smaller implants. The choice between the two depends on the specific clinical needs, load requirements, and anatomical considerations of the patient.

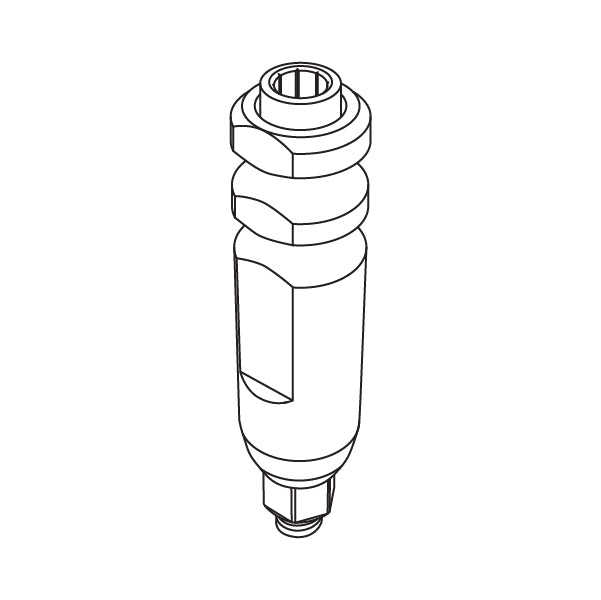

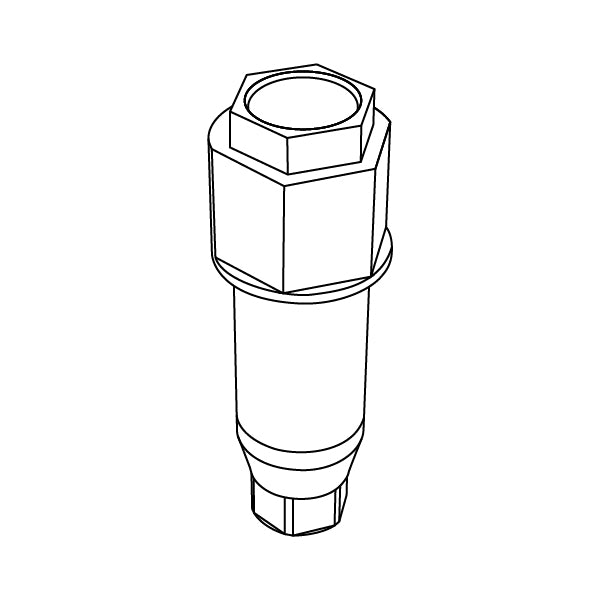

Multi-unit abutments provide the least lateral offset and greatest range of angulation correction when dealing with dental restorative procedures. This unique property allows them to ensure simplicity of use, versatility of applications, and uncompromised strength.

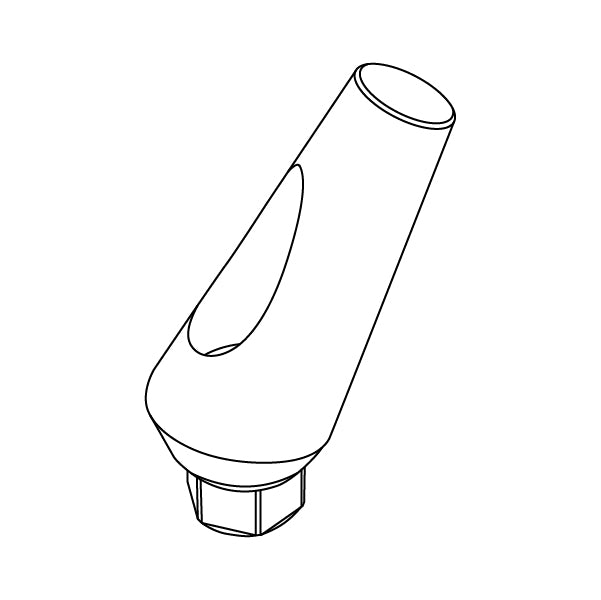

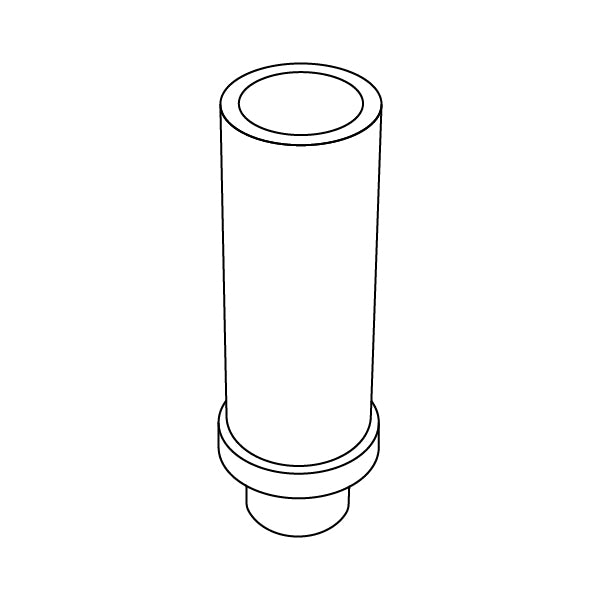

Multi-unit abutments with angle correction capabilities are essential for achieving optimal prosthetic outcomes in dental implantology. The choice between 17-degree, 30-degree, or 45-degree abutments depends on the degree of implant angulation and the specific clinical scenario. These abutments help align the prosthesis with the dental arch, ensuring improved aesthetics, function, and patient satisfaction. Additionally, multi-unit abutments are available in different lengths, usually ranging from 1mm to 3mm, to accommodate various clinical needs.

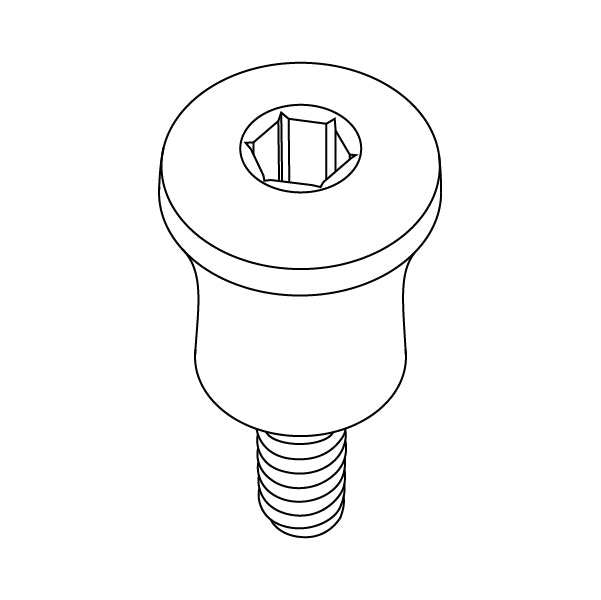

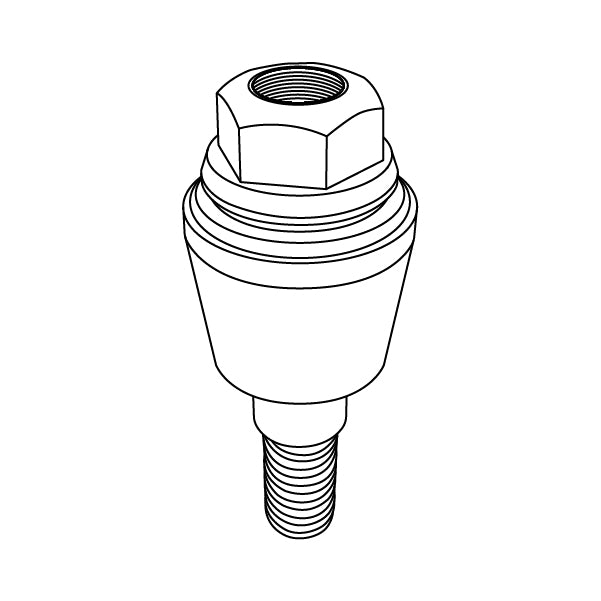

Placing and adjusting angulated multi-unit abutments involves first evaluating the implant positions to select the appropriate abutment angle (17°, 30°, or 45°) and length (1mm, 2mm, or 3mm). The abutment is then screwed onto the implant and tightened with a recommended torque of 35 Ncm. The fit and angulation are verified by placing the prosthetic framework or temporary restoration, ensuring proper alignment and occlusion.

Adjustments are made as needed by repositioning the abutment or selecting a different angle. Once the optimal fit is confirmed, the abutment is securely tightened, and the final prosthesis is attached. Any necessary adjustments to the prosthesis are made to ensure comfort and proper function. Patients are instructed on care and maintenance, with follow-up appointments scheduled to monitor the abutment and prosthesis.

Angulated screw channel technology is a process that is used to place screw-retained restorations in cases where implant placements are not ideal. This is usually done to prevent late-stage implant failure due to improper or excessive use of dental cement.

Using this technique, the dentist can correct angles of up to 25 degrees deviation from the path of the abutment screw to the implant channel. These can be torqued to 35ncm and reconciled. Being able to correct implant deviation from the long axis of ideal tooth position with angled abutments has been well documented and proven to produce good results when dealing with cement-retained restorations.