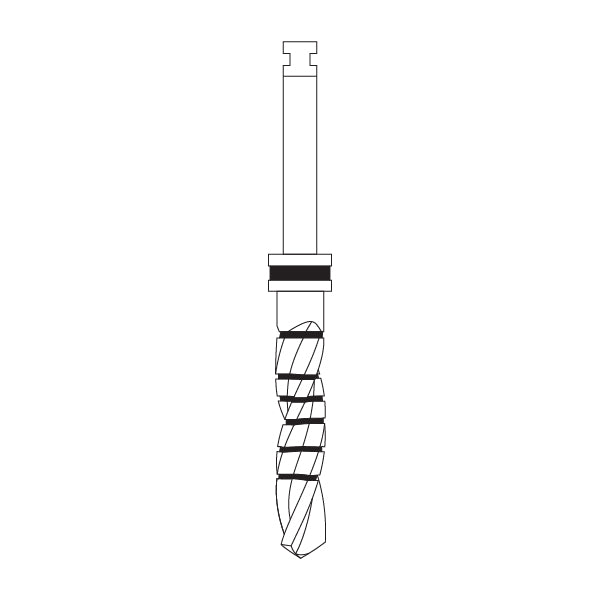

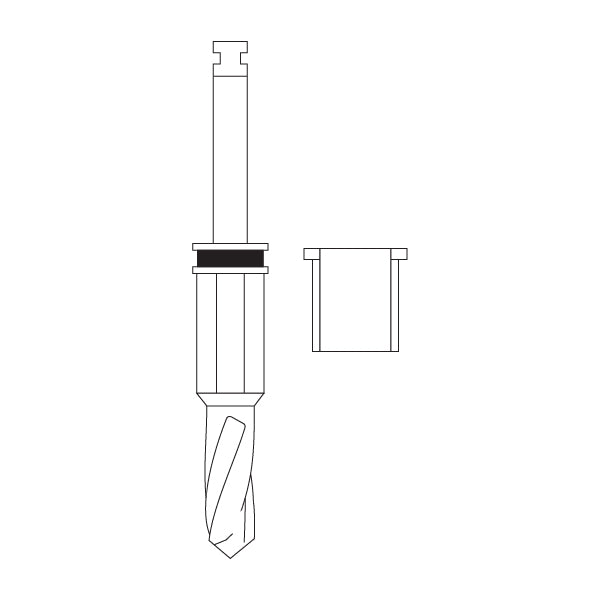

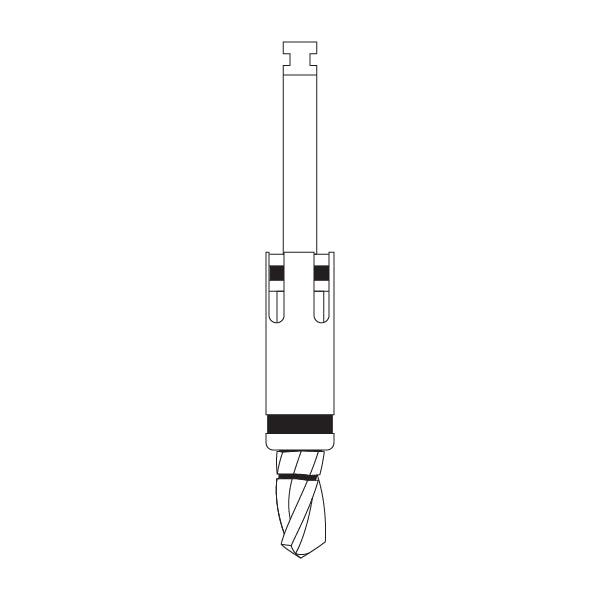

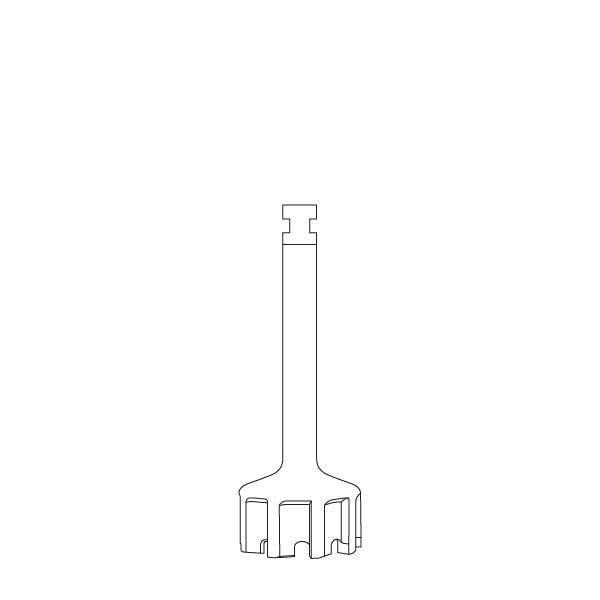

Integral stopper drills are designed with built-in stoppers to control drilling depth accurately.

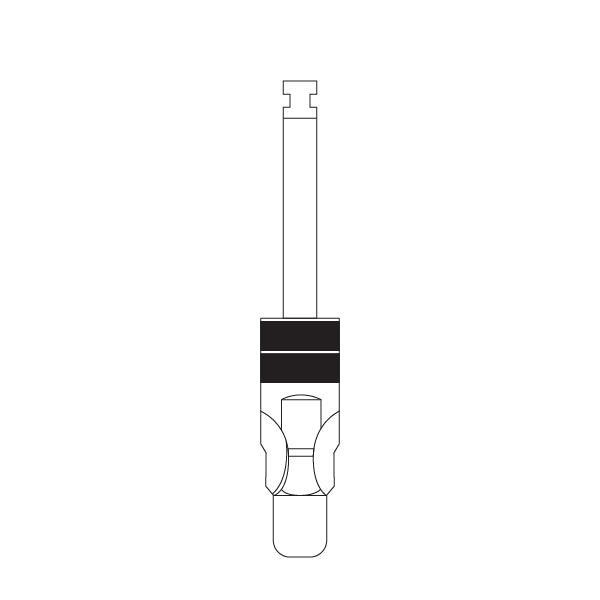

Crafted from stainless steel to ensure precise and safe osteotomy procedures. We also offer a DLC-coated option for enhanced durability and cutting performance.

Their integral stoppers provide consistent depth control, minimizing the risk of over-drilling and enhancing the overall success of implant placement.

Open Description

FAQs

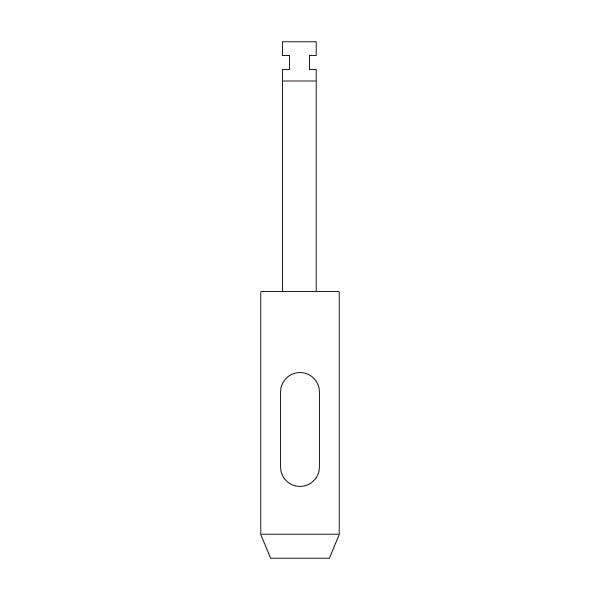

GDT Implants' Integral Stopper Drills are designed to enhance surgical precision by incorporating built-in stoppers that ensure consistent drilling depth. This feature is crucial in avoiding over-drilling or insufficient depth, which can compromise implant stability. The integral stopper eliminates the need for external stoppers, reducing the risk of errors during surgery. By providing a clear and predefined drilling depth, these drills contribute to the overall accuracy of the implant placement, leading to improved outcomes in both immediate and long-term stability of the implant.

GDT Implants' Integral Stopper Drills are available in two material options. The stainless steel version is designed for strength, corrosion resistance, and reliable cutting performance. It maintains its sharpness through multiple uses, ensuring consistent results. The DLC (Diamond-Like Carbon) coated version offers added features, including enhanced wear resistance, reduced friction, and increased longevity. This coating helps to minimize heat generation during drilling, further preserving the drill's integrity and extending its lifespan, making it a versatile choice for demanding procedures.

GDT Implants' Integral Stopper Drills offer significant clinical advantages, including enhanced safety and efficiency during implant placement. The built-in stopper mechanism provides a fail-safe against over-penetration, protecting vital anatomical structures like nerves and sinuses. This feature is particularly beneficial in complex cases where precision is critical. Moreover, the efficiency of these drills reduces the time needed for drill changes, streamlining the surgical process. The result is a more predictable and controlled drilling experience, leading to better clinical outcomes for patients.

The precise depth control offered by our Integral Stopper Drills plays a crucial role in ensuring optimal implant placement, which is key to the long-term success of restorations. By preventing over-drilling and ensuring that the implant is seated at the correct depth, these drills help achieve ideal primary stability. This stability is essential for the proper osseointegration of the implant, which directly influences the longevity of the restoration. Additionally, the use of high-quality materials in these drills ensures consistent performance over time, supporting long-lasting implant outcomes.