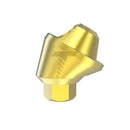

How does the 30° angulation of the Angulated Multi-Unit 1.4 Abutment benefit clinical outcomes?

Why is the 1.4mm profile height significant for GDT Implants’ Angulated Multi-Unit 1.4 Abutment?

What materials are used in the construction of the GDT Implants Angulated Multi-Unit 1.4 Abutment, and what are their clinical advantages?

How does the Angulated Multi-Unit 1.4 Abutment support efficient prosthetic workflow in complex cases?